For optimal handling, prioritize maintaining the rods connecting your vehicle’s wheels. Regular inspections can prevent misalignment, ensuring smooth maneuvering even in challenging conditions. Keep in mind that worn components may lead to unpredictable reactions, especially during high-speed driving.

Consider upgrading to high-quality materials to enhance performance. Steel or alloy options tend to provide more durability than standard parts, significantly reducing risks of failure. Replacement intervals should align with manufacturer recommendations, typically suggested every 50,000 miles, but drivers should assess wear for personalized maintenance schedules.

Lastly, consult a certified technician if you experience unusual vibrations or difficulty maintaining direction. Prompt action can save costs associated with more extensive repairs while securing reliable operation on the road.

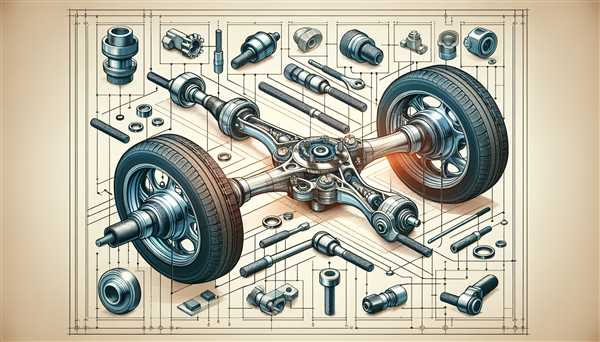

Understanding the Role of Tie Rods in Vehicle Steering Mechanics

For optimal handling, ensure that these components are regularly inspected for wear and damage. Located in the front suspension system, they link the steering gear to the steering knuckles, facilitating precise movement of the wheels. A tight connection assists in transmitting driver input directly to the wheels, enhancing responsiveness.

Pay close attention to the alignment; improper adjustments can lead to uneven tire wear and compromised control. Loose connections can cause vibrations, clunks, or wandering in your vehicle’s path, indicating the need for immediate examination. Utilizing high-quality replacements can significantly improve performance and safety.

Regular maintenance of the ball joints attached to these links is equally important. Inspect seals for leaks and ensure that all fittings are free of dirt and debris to maintain seamless operation. When replacing, consider upgrading to heavy-duty versions designed for specific driving conditions, which can provide increased durability and reliability.

Keep an eye on the steering response when driving. Any delay or lack of precision suggests that something might be off with these key elements. Addressing issues promptly decreases the risk of further damage and enhances the overall driving experience.

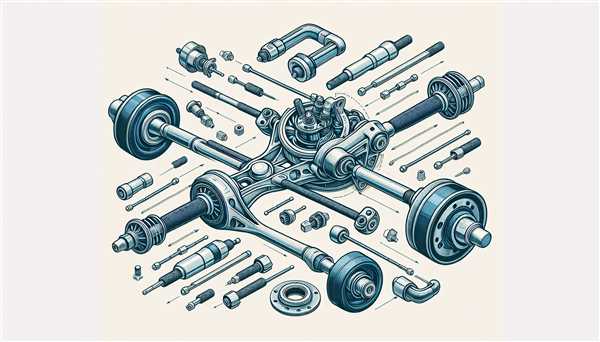

Signs of Worn Tie Rods and Their Effects on Steering Precision

Listen for clunking or popping noises while turning; this indicates potential wear in components. Uneven tire wear is another clear sign of misalignment often caused by worn parts. A noticeable increase in steering play may also suggest deterioration, making precise control challenging.

Watch for a vibration in the steering wheel, especially during acceleration. This may signal a failure of connecting elements affecting directional control. A hesitant or unresponsive feel while driving can compromise handling, leading to difficulty in navigating corners safely.

If the vehicle drifts or wanders without input, a thorough inspection of connection components is necessary. Enhanced feedback can also diminish, indicating disconnection between the steered wheels and the driver’s input. All these signs require immediate attention to maintain safety and responsiveness.

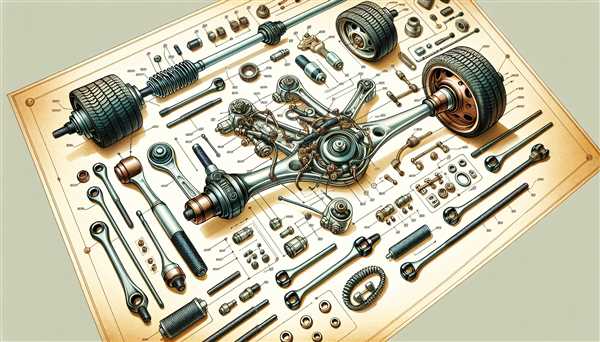

Maintenance Tips for Ensuring Optimal Tie Rod Performance

Regular inspections of components connected to the steering mechanism can prevent issues before they escalate. Examine the joints and boots for wear or damage, replacing any deteriorated parts immediately.

Keep the areas around pivot points clean to avoid the buildup of dirt and debris. This ensures smooth movement and reduces the chances of parts seizing up in adverse conditions.

Check for any signs of excessive play or movement in the connectors. Tightening bolts to manufacturer specifications can help maintain precision alignment and enhance handling.

Consider periodic lubrication of joints, using appropriate grease, to minimize friction and prolong the lifespan of the assembly.

Monitor tire wear patterns closely. Uneven wear could indicate misalignment caused by degraded linkages. Realigning the wheels can improve performance and safety.

Schedule routine professional inspections, especially after harsh driving conditions, to assess all related elements. Technicians can provide valuable insights into the integrity of these apparatuses.

Maintain proper wheel alignment and balance, as they directly affect the behavior of the whole system. Regular checks can prevent unnecessary strain on the mechanisms.