For optimal vehicle performance, routinely inspect suspension linkage components, particularly linkages and cushioning units. These elements are fundamental in maintaining stability and ensuring a smooth ride. Neglecting them can lead to increased tire wear and compromised handling capabilities.

Regular maintenance of linkages should include checking for signs of wear or damage, such as cracks or excessive play. Replacing worn cushioning units can significantly enhance ride comfort and prolong the lifespan of the entire suspension system. If you experience unexpected noise or harsher road feedback, it’s crucial to assess these parts without delay.

Consider upgrading to higher-quality or performance-oriented linkages for more demanding driving conditions. Enhanced components can provide better articulation and more precise handling, especially in high-performance or off-road scenarios. Prioritizing the condition of these suspension elements can greatly contribute to the overall driving experience.

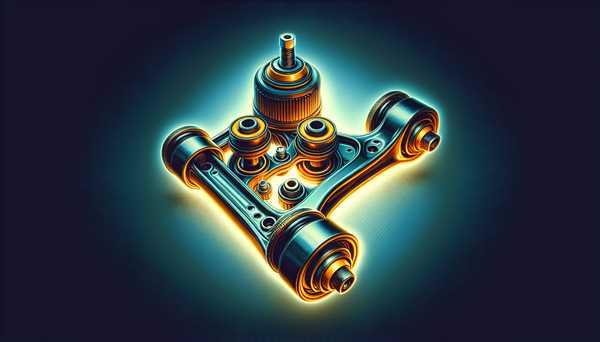

How Control Arms Affect Vehicle Handling and Stability

Proper alignment of suspension linkages is key for optimizing vehicle dynamics. Components connecting wheels to the chassis ensure the vehicle remains stable during cornering and abrupt maneuvers.

Precision in manufacturing these parts can lead to improved responsiveness in steering. Enhanced firm connections between the chassis and wheel assemblies allow for better feedback from the road, which translates into enhanced driver control.

Worn or damaged connection points can lead to unpredictable handling characteristics. This usually manifests as excessive play or vibration, which can compromise safety. Regular inspections are necessary to assess the condition of bushings, as they wear down over time, affecting both ride comfort and stability.

Choosing high-quality aftermarket components can significantly enhance steering precision and overall vehicle control. Upgraded materials may provide additional damping, which minimizes harsh impacts from uneven road surfaces.

Maintaining proper torque specifications during installation is crucial for achieving appropriate performance levels. Anomalies in installation can lead to uneven tire wear, negatively affecting grip and control.

Correct adjustments during wheel alignment after replacement or repair can further enhance handling characteristics by ensuring all components work harmoniously together. Understanding suspension geometry is essential for achieving optimal performance in various driving conditions.

The Role of Bushings in Minimizing Noise and Vibration

To reduce noise and vibration, select high-quality elastomeric components designed with specific durometers. Softer materials absorb impact better, while firmer options enhance stability.

Incorporate rubber or polyurethane to ensure adequate cushioning, allowing for better resilience and suppression of unwanted sound. Regular inspection is critical; inspect for wear, cracking, or degradation to maintain optimal performance.

Investing in upgraded suspension elements with enhanced dampening properties can drastically improve ride quality. Pay attention to installation; proper seating is vital to avoid misalignment and premature wear.

- Choose components that match vehicle specifications for compatibility.

- Replace worn-out parts promptly to avoid further issues.

- Opt for press-fit designs over slip-fit to enhance durability.

Finally, consider the overall geometry of your suspension system. Proper alignment of various components contributes significantly to minimizing unwanted noise and vibrations, ensuring a smooth driving experience. Regular maintenance can drastically extend the lifespan of these elements and enhance vehicle performance.

Signs of Wear in Control Arms and Bushings: When to Replace

Noticing clunking or knocking noises while driving can indicate issues with suspension components. If you hear these sounds when going over bumps or turning, it might be time to inspect your objects.

Excessive vibration in the steering wheel, especially during acceleration, can denote degraded fixtures. This symptom suggests that the mounts are failing, requiring examination.

Uneven tire wear is a direct consequence of compromised fixtures. If you observe uneven patterns, inspect the structure for damage or deterioration that may necessitate replacement.

A misaligned steering wheel while driving straight signals potential problems in attachments. If the vehicle pulls to one side, it’s advisable to assess the components for wear.

Fluid leaks around the mounts can also indicate failure. A noticeable leak requires immediate attention, as it compromises the integrity of the assembly.

Lastly, a visual inspection revealing cracks, splits, or other forms of physical damage indicates significant wear. If any of these signs are present, prioritizing a replacement is essential to maintain vehicle safety and performance.