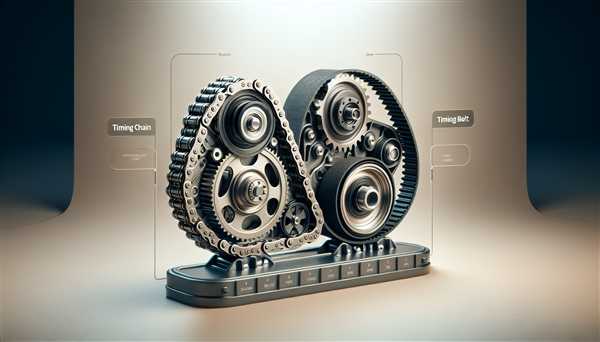

For optimal engine performance, ensure you comprehend the structural makeup of your vehicle’s timing apparatus. Two primary configurations govern the synchronization of engine components: the robust metal chain and the resilient rubber belt.

The chain boasts a longer lifespan, often reaching upwards of 200,000 miles, while exhibiting strength against wear and tear. Its design allows for minimal stretching, ensuring that precision in timing is maintained over extensive periods, which is advantageous for high-performance engines.

Conversely, the belt, typically engineered from durable rubber, comes at a lower initial cost and is lighter weight. However, it necessitates more frequent replacements, generally around 60,000 to 100,000 miles. This can lead to increased maintenance expenses over time, making it essential to stay ahead of replacement schedules.

Evaluating these attributes can guide you in making an informed choice that aligns with your vehicle’s requirements and your maintenance preferences. Understanding these elements not only aids in preserving your engine’s integrity but can also enhance its overall longevity.

Durability and Lifespan Comparison

A timing belt typically lasts between 60,000 to 100,000 miles, depending on the vehicle manufacturer’s recommendations. Regular checks are advisable to identify any signs of wear.

In contrast, a chain often boasts a lifespan exceeding 100,000 miles, with some lasting the entire life of the engine if properly maintained. Periodic inspections are still essential, as they can wear or stretch over time.

Factors influencing durability include engine design, operating conditions, and maintenance practices. For high-performance engines, a belt’s lifespan may decrease due to added stress, while a chain may endure better under similar conditions.

Replacing a degraded belt can prevent significant engine damage, while a failing chain could result in severe engine failure. Consider your driving habits and vehicle type when choosing the appropriate component for reliability and longevity.

Maintenance Requirements and Costs

Inspect the belt every 60,000 to 100,000 miles, as failure can lead to significant engine damage. Replace it at the manufacturer’s recommended intervals to avoid costly repairs.

Regular checks for wear, fraying, or cracking are crucial. A visual inspection should be part of routine service. Listen for unusual noises during engine operation, which may indicate a problem.

Costs for replacement vary widely. The average price for a belt replacement ranges from $500 to $1,000, including parts and labor. This is generally less than the price for a chain overhaul, which may exceed $1,500 depending on the vehicle.

Using high-quality parts can impact longevity and performance. Avoiding cheap alternatives might save money initially but can lead to greater costs down the road if premature failure occurs.

Service intervals can differ based on vehicle type. Always consult the owner’s manual for the specific guidance tailored to your engine. Tracking maintenance can prevent unexpected expenses and extend the life of both internal components and the engine.

Impact on Engine Performance and Efficiency

The choice between a chain and a belt significantly influences engine output and fuel consumption. A chain typically provides precise valve timing, enhancing combustion efficiency and power generation. This improved synchronization leads to better responsiveness, particularly at high RPMs.

Conversely, a belt offers quieter operation but may result in slight delays in timing adjustment, potentially compromising performance under demanding conditions. However, belts are generally lighter, which reduces rotational mass and can enhance fuel economy in certain applications.

Durability is another factor affecting performance; chains often last longer, which means they maintain optimal timing for extended periods without requiring replacement. Belts require regular inspection and replacement, as deterioration can lead to timing issues, impacting efficiency and power output.

In summary, consider a chain for high-performance engines desiring durability and responsiveness, while a belt may suit lighter, quieter vehicles focused on fuel savings.