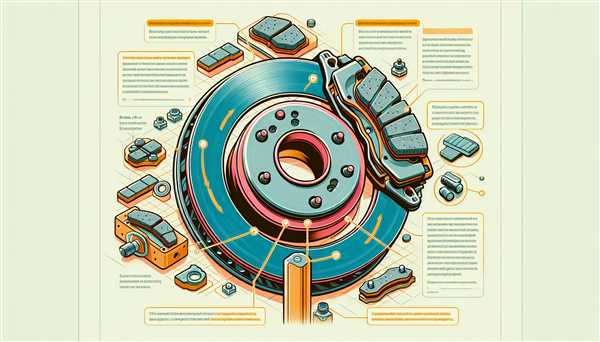

Regular inspection of stopping components is recommended to ensure optimal performance. Pay attention to thickness indicators on these elements; a reduction below manufacturer specifications suggests replacement is necessary.

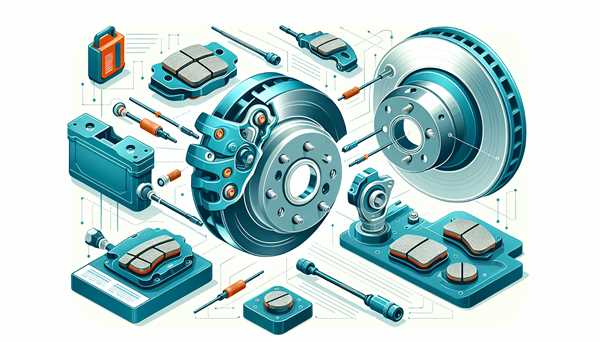

Choosing appropriate materials enhances stopping efficiency. Organic, metal, or ceramic varieties each offer distinct attributes. Organic options provide quieter operation, while metallic varieties excel in high-temperature conditions, and ceramics strike a balance between both.

Observe any signs of uneven wear or vibration during usage. Such symptoms can indicate alignment issues or imbalances in components, necessitating professional evaluation. Prioritizing quality over cost can significantly impact longevity and performance.

Be aware of noise production, which often signals the need for replacement. Ignoring these auditory warnings can lead to further complications. Regular maintenance enhances both safety and driving enjoyment.

Choosing the Right Brake Pads for Your Vehicle

Opt for ceramic variations for reduced noise and dust. They excel in daily driving conditions, providing longevity and consistent performance. Consider semi-metallic types if you prioritize powerful stopping ability, especially for larger vehicles or towing situations.

Verify compatibility with your model by checking the manufacturer’s specifications. Installing incorrect components can lead to premature wear or ineffective braking. Always confirm that the thickness of the new units matches the design of your current setup.

Evaluate the temperature range of the options. If you frequently drive in mountainous areas or engage in spirited driving, high-performance choices designed for elevated heat conditions will outperform standard selections.

Assess your driving style; aggressive drivers may benefit more from quick-response heavy-duty models. For more relaxed or suburban commuting, standard variants may suffice without sacrificing safety.

Price should align with quality. High-quality materials ensure durability, so consider established brands known for reliability. Reading user reviews can provide insight into real-world performance and longevity.

Finally, have your new components installed by a professional to guarantee optimal performance. Proper installation significantly impacts safety and the lifespan of all related parts.

Signs of Worn Brake Rotors and Their Impact on Safety

Listening for unusual sounds during operation is essential. A grinding or squealing noise typically indicates wear. Additionally, feel for vibrations or pulsing when pressure is applied; this suggests uneven surfaces that compromise performance.

Another sign includes a shuddering sensation felt through the steering wheel during stopping. This occurs due to uneven wear or warping. Drivers should also monitor brake pedal response; if it feels spongy or requires excessive pressure, service may be necessary.

Moreover, regular inspections are key to maintaining vehicle safety. Visual deterioration, such as cracks, grooves, or discoloration, should not be overlooked. If the thickness measurements are lower than manufacturer specifications, immediate action is warranted.

Neglecting these indicators increases the risk of accidents due to decreased stopping capacity. The efficiency of the entire braking system is affected, leading to potential harm on the road. Prioritize replacements to ensure safety and reliability in vehicle operation.

Maintenance Tips for Extending the Life of Brake Components

Regular inspections are key. Check the thickness of the pads and the condition of the rotors every 5,000 to 10,000 miles.

Keep the brake system clean. Dirt and debris can cause uneven wear. Use brake cleaner to keep surfaces clear.

Use quality replacements. Invest in high-performance friction materials to enhance durability and reduce wear.

Ensure proper installation. Misalignment can lead to premature failure. Always follow manufacturer specifications.

Monitor driving habits. Avoid sudden stops and aggressive driving. Smooth acceleration and gentle braking extend component life.

Consider brake fluid condition. Change the fluid every 1 to 2 years to prevent moisture buildup and corrosion.

Inspect for noise. Squeaking or grinding sounds can indicate that components are wearing out and need attention.

Check the hardware. Ensure that all mounting components are in good condition and properly secured.

Rotate tires regularly. Balanced wear on tires can lead to even brake performance, reducing strain on components.

Watch for vibrations. Any shaking while braking may indicate warped rotors that require immediate inspection.

Consider environmental factors. Driving in hilly areas can increase wear; adjust habits and maintenance accordingly.